This is Part Two of our History of PVE series – read Part One here.

By 2000, Lee Miller and his dad Levi had a proven track record of making the right decisions for Paint Valley Equipment’s growth. The company had become one of Ohio’s largest used heavy construction equipment dealers, and sales of their own parts had increased year after year. Lee, now his dad’s partner in the company, started to know the meaning of having “skin in the game.”

Lee describes the situation right after the 9/11 tragedy in 2001. “That almost crashed our cash flow. We had our worst sales month ever. That event took the optimism out of the air. If your client base isn’t optimistic, they aren’t buying.” Looking back, Lee believes an optimistic nature and determination—things his dad instilled in him—were key ingredients in his ability to handle the hard times as an owner of a company.

Lee relied on Levi’s engineering skills, and Levi relied on Lee’s interpersonal skills. Together, they were a strong force, and they led the way for lots of changes in the 2000s.

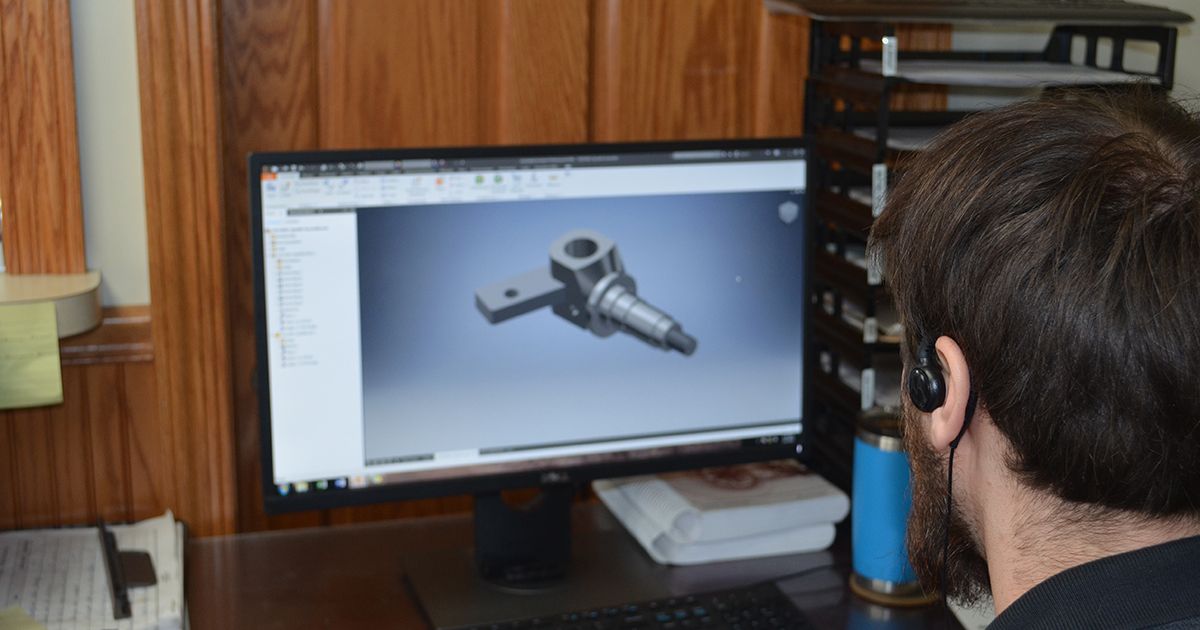

By 2003, PVE stopped selling used parts. It made more sense to them to spend that energy on the engineering and production of new parts. They were right; the new parts business experienced 15-18% growth for five consecutive years.

Lee says, “I knew I was in over my head in business management; I didn’t have any background or education in it.” But Lee knew what to do about that: “First, I went to the Lord and said I cannot do this on my own—you lead, I’ll follow. I can look back on those crazy years in the early to mid-2000s and know that I got the guidance I needed. I latched on to a few people who were successful. I got great advice from the right people. And we hired the right people. You can hire people who are smarter than you, and that’s good.”

One of Lee’s top priorities was to put someone in place to improve PVE’s work culture. Lee understood that the right culture is what makes it possible to attract and keep the best talent. Lee looks back today and marvels at the impact that person has had. “All of us are in this together, with values such as honesty, integrity, listening to people—those things matter.”

At the same time that PVE started to build the right culture, they started to build something else: a 12,000-sq.-ft. facility on the property. That project resulted in another key hire. In 2005, they hired someone to manage the construction site, and today he manages all production!

From 1990-2004, PVE had built all their new parts in 14 satellite facilities—machine shops and welding shops scattered within 30 miles of the business. The purpose of the new building was to bring a lot of the work in-house; that happened, but they still continued to use their subcontractors (satellite places) as well.

Two major changes took place in 2007: the implementation of an ERP system (process management software), which allowed for easier management of data and much better service to customers; and the move to sell to dealers only, eliminating all retail sales. PVE saw an immediate spike in dealer sales. Lee explains, “Dealers had new confidence in us, since we were no longer competing with them.”

This spike led to the need for yet more workspace. PVE constructed a second 12,000-sq.-ft. facility in 2008. Once the building was complete, they were able to give their subcontractors the option to work onsite. This development reduced the logistics challenges they had long endured and vastly improved efficiency and quality.

By this time, Levi had become an expert in workflows, quality control, and logistics. He had excelled at the planning that was necessary back when all their work was done in satellite facilities, so it was no surprise that he embraced the challenge of designing workflows for the new buildings. And it wasn’t just the workflows; he worked to configure the buildings so that the workflows could become a reality.

All of the strides made in the 2000s put PVE on a solid foundation. They had learned how to adapt and sustain growth, and they have been off to the races ever since. In 2012, they stopped buying and selling used equipment; the margins were not what they used to be, and the new parts business was stronger than ever.

Once PVE dedicated all their resources to manufacturing, their increased sales caused them to outgrow their space once again. A new building was built in 2014, and they are bursting at the seams again, today employing about 60 people. The past five years have been strong years. They believe their growth is a direct result of being able to give their customers exactly what they want.

Lee points out that he and his dad started as farmers and mechanics, proving that ordinary people can do big things. And the biggest thing they did? “We built a great team. Today, both Dad and I could leave for an extended period of time, and the company would run fine. The expertise and dedication of our team—that’s the most rewarding part of our history.”

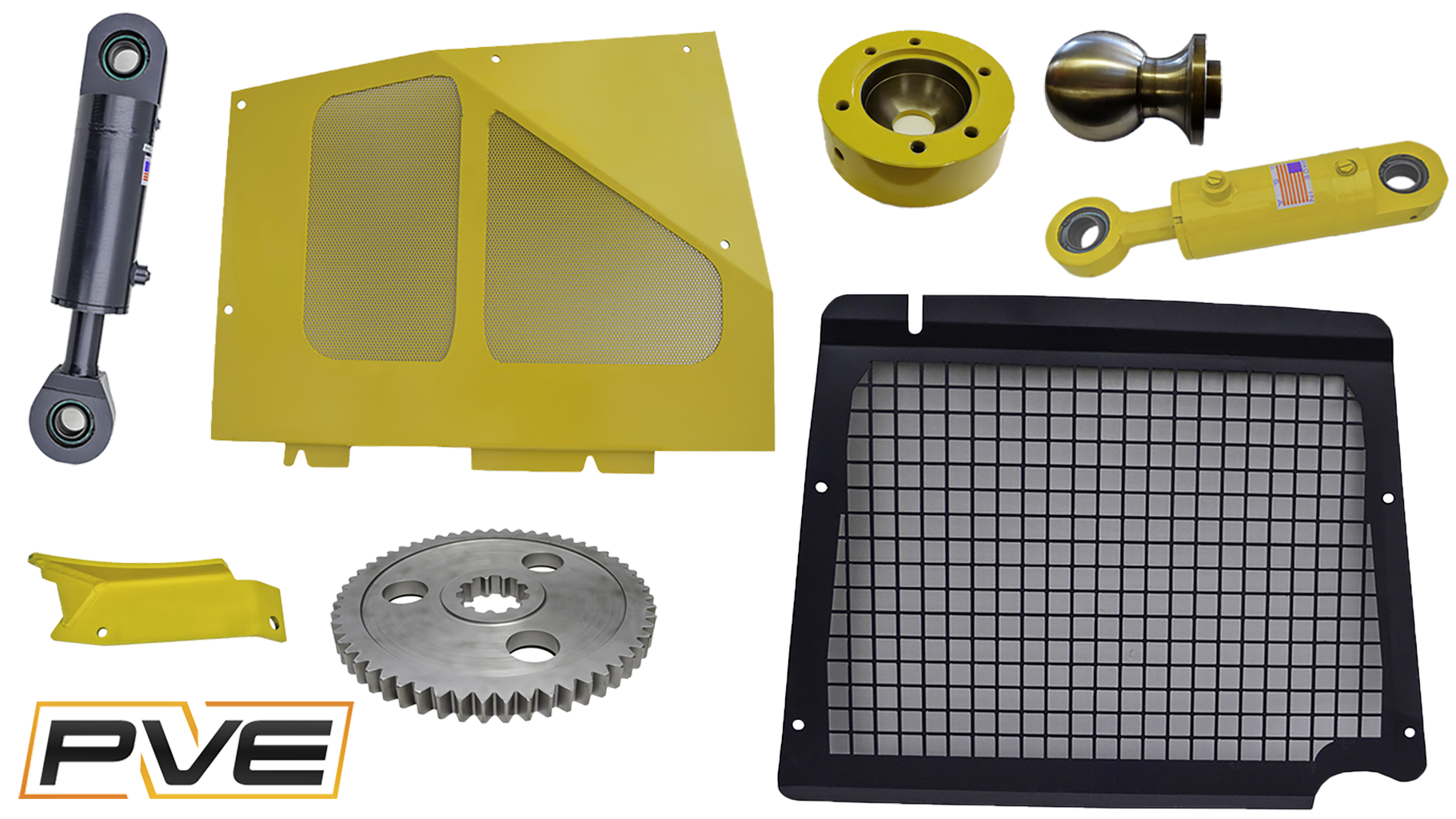

PVE is committed to bringing only the highest quality heavy construction equipment parts to market. Our QC Department follows a highly detailed, professional process to ensure that only the best products leave our doors.

PVE is committed to bringing only the highest quality heavy construction equipment parts to market. Our QC Department follows a highly detailed, professional process to ensure that only the best products leave our doors.

We have added and will continue to bring parts into production in the following part categories:

We have added and will continue to bring parts into production in the following part categories: